1. Cranes

A crane is a type of machine, equipment usually equipped with lifting ropes, ropes, cables or chains and pulleys , which can be used to raise and lower materials and move them along horizontal. Cranes mainly used to lift heavy objects and transport them to other places. Equipment that uses one or more simple machines to give mechanical advantage and thereby move loads beyond normal human capacity. Cranes are commonly used in transportation to load and unload goods, in construction to move materials, and in manufacturing to assemble heavy equipment.

The first known crane was the shaduf (Water towbar - One end attached to a water dispenser, the other to a heavy weight, shaped like a lever), a water lifting device invented in ancient Mesopotamia (modern Iraq) and later appeared in ancient Egyptian technology. Construction cranes later appeared in ancient Greece, where they were powered by men or animals (such as donkeys), and used to construct buildings. Larger cranes were later developed in the Roman Empire, using human wheels, allowing heavier loads to be lifted. In the High Middle Ages, harbor cranes were introduced to load and unload ships and assist in their construction — some were built into stone towers for added durability and stability. The first cranes were built from wood, but cast iron, iron and steel took their place after the Industrial Revolution.

For centuries, energy was provided by human or animal physical activity, although hoists in watermills and windmills could be driven by harnessed natural forces. The first mechanical power was provided by a steam engine, the earliest steam cranes were introduced in the 18th or 19th century, many of which remained well used by the end of the 20th century. Modern cranes typically use internal combustion engines or electric motors and hydraulic systems to provide much greater lifting capacity than in the past, although manual cranes are still used when power supply is uneconomical.

There are different types of cranes, each suited to a specific use. There are a variety of sizes from the smallest crane, used in workshops, to the tallest tower crane, used for the construction of high-rise buildings. Mini cranes are also used for the construction of tall buildings, in order to facilitate constructions by accessing tight spaces. Large floating cranes are commonly used to build oil rigs and salvage sunken ships.

Some lifting machines do not fully fit the above definition of crane, but are commonly referred to as cranes, such as stacker cranes and load cranes.

2. Crane history

Late Antiquity

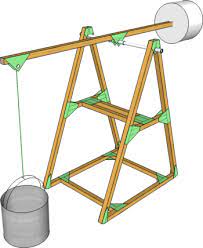

The first type of crane is the shadouf, which has a lever mechanism and is used to lift irrigation water. It was invented in Mesopotamia (modern Iraq) around 3000 BC. Later, shadouf appeared in ancient Egyptian technology around 2000 BC.

Ancient Greece

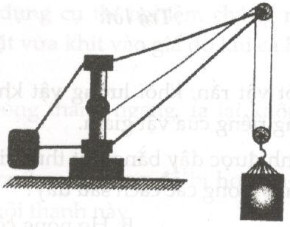

Greco-Roman Trispastos ("Three-pulley crane"), simple crane (150 kg load)

Cranes for lifting heavy objects were developed by the ancient Greeks in the late 6th century BC. Archaeological records show that no later than 515 BC special cuttings used for lifting clamps began to appear on the rock formations of Greek temples. Because these holes are directed at the use of a lifting device, and because they are found either above the center of gravity of the mass or in pairs equidistant from a point from the center of gravity, they are considered positive by archaeologists. proof of the existence of a crane is required.

The introduction of winches and pulley hoists soon led to the widespread replacement of ramps as the primary means of vertical motion. Over the next 200 years, constructions in Greece saw a dramatic reduction in the weight handled, as new lifting techniques made it more practical to use several small stones than with fewer large stones. In contrast to the antiquity with its increasing block size pattern, classical Greek temples such as the Parthenon always had stone blocks weighing less than 15–20 tons. In addition, the practice of erecting large monolithic columns was practically abandoned in favor of using a number of empty columns.

Although the exact circumstances of the transition from crane technology to crane technology are still unclear, it is suggested that Greece's volatile social and political conditions are more suitable. with the employment of small professional construction crews rather than large numbers of unskilled workers, making cranes preferable to the Greek Polis on the more labor-intensive ramps that are the norm in many industries. autocratic society of Egypt or Assyria.

The first clear literary evidence for the existence of a complex pulley system appears in Problems of Mechanics (Mech. 18, 853a32–853b13) by Aristotle (384–322 BC), but is probably invented work a little later. Around the same time, the block sizes at the Greek temples began to match those of their ancient predecessors, suggesting that the more complex pulley must have found its way to the sites. building point of Greece at that time.

Ancient Roman Empire

The golden age of cranes in antiquity came during the time of the Roman Empire, when construction activity skyrocketed and buildings reached colossal sizes. The Romans bred the Greek crane and developed it further.

The simplest Roman crane, the trispastos, consisted of a single crane, a winch, a rope, and a block containing three pulleys. Thus, having a mechanical advantage of 3:1, it has been calculated that a single man working on the winch can lift 150 kg (330 lb) (3 pulleys x 50 kg or 110 lb = 150). ), assuming that 50 kg (110 lb) represents the maximum effort a man can exert over a longer period of time. Heavier cranes have five pulleys (pentaspastos) or, in the largest case, a set of three - five pulleys (Polyspastos) and come with two, three or four masts, depending on the maximum load. multi. The polyspastos, when worked by four men on both sides of the winch, can easily lift 3,000 kg (6,600 lb) (3 ropes x 5 pulleys x 4 men x 50 kg or 110 lb = 3,000 kg or 6,600). lb). If the winch were replaced with a wheel, the maximum payload could be doubled to 6,000 kg (13,000 lb) with only half the crew, as the wheel has a much greater mechanical advantage due to its large diameter. than. This means, compared to the construction of the ancient Egyptian pyramids, where it took about 50 men to move a 2.5 ton block of stone [which?] up the ramp (50 kg (110 lbs.) lb)/person), the lifting capacity of the Roman polyspastos was 60 times higher (3,000 kg or 6,600 lb/person).

However, many of the surviving Roman buildings have stone blocks much heavier than those handled by polyspastos indicating that the overall lifting capacity of the Romans far exceeded any single crane.

It is thought that Roman engineers lifted these extraordinary weights by two means: First, at Heron's suggestion, a lifting tower was established, with four masts arranged in a quadrangle. parallel. sides, not like a siege tower, but with columns in the middle of the structure (Mechanica 3.5). Second, a multitude of caps are placed on the ground around the tower, although having a lower leverage ratio than the wheel, the caps can be set to a higher number and operated by more than one person. over (and further, by animal drag). This multiple use of capstans was also described by Ammianus Marcellinus (17.4.15) in connection with the lifting of the Lateranense tower in the Circus Maximus (circa 357 AD). The maximum lifting capacity of a single cap can be established by the number of iron holes drilled into the monolith. In the case of the Baalbek storage blocks, weighing between 55 and 60 tons, the eight extant holes indicate an allowance of 7.5 tons per iron lewis, i.e. per capstan. Lifting such heavy loads in a coordinated action requires the smooth coordination of work groups that exert force on the bows of the boat.

Middle Ages

During the High Middle Ages, wheeled cranes were reintroduced on a large scale after the technology fell out of use in Western Europe with the fall of the Western Roman Empire. In navigation, the earliest use of harbor cranes is recorded for Utrecht in 1244, Antwerp in 1263, Bruges in 1288, and Hamburg in 1291, while in England, wheeling is not recorded before 1331.

In general, vertical transport can be done by crane safely and less expensively than conventional methods. Typical areas of application are harbors, mines and especially construction sites where wheeled cranes play a pivotal role in the construction of lofty Gothic cathedrals. However, both archival and photographic sources of the time suggest that newly introduced machines such as wheelbarrows or wheelbarrows did not completely replace more labor-intensive methods such as ladders. , hoes and wheelbarrows. Instead, old and new machinery continued to exist on medieval construction sites and harbors.

In addition to the wheels, medieval depictions also show the crane being manually powered by windscreens with radiator spokes, cranks and, in the 15th century, also windscreens in the shape of a ship's wheel. To smooth out abnormal impulses and overcome 'dead spots' during lifting, flywheels are known to have been used as early as 1123.

The exact process by which the wheeled crane was reintroduced is not recorded, although its return to the construction sites is certainly considered to be closely related to the simultaneous development of ants. Gothic architecture. The re-emergence of wheeled cranes may be the result of technological developments in winches from which the wheel has evolved structurally and mechanically. Alternatively, the medieval wheel may represent an intentional reproduction of its Roman counterpart taken from the architect De Vitruvius, which is available in many monastic libraries. Its reintroduction may also have been inspired by the observation of the labor-saving qualities of the waterwheel with which the original wheels shared many structural similarities.

Structure and location

The medieval wheel was a large wooden wheel that revolved around a central axis with a passage wide enough for two workers to walk side by side. While the earlier 'compass swingarm' wheel had spokes driven directly into the center axle, the more advanced 'lever lever' had arms arranged like wires to the wheel rim. , which gives the possibility of using a thinner shaft and provides therefore a greater mechanical advantage.

Contrary to popular belief, the cranes on medieval construction sites were neither placed on the extremely light scaffolding used at the time nor on the thin walls of Gothic churches without ability to withstand the weight of both the lifter and the load. Rather, the crane is placed in the early stages of construction on the ground, usually within the building. When a new floor is completed and the large bracing of the roof joins the walls, the crane is dismantled and reassembled on the roof beams from where it was moved from bay to bay during construction. tunnels. So the crane "grow up" and "wandered" to the building with the result that today all construction cranes still standing in the UK are found in the church towers above the arch and below. roof, where they stay after construction is complete to carry repair materials up.

Less often, medieval lightings also show cranes mounted outside the walls with machine racks fixed to slings.

Mechanics and Operation

Tower crane at Trier inland harbor from 1413.

In contrast to modern cranes, medieval cranes and gantry cranes - like their counterparts in Greece and Rome - were primarily capable of vertical lifting, nor were they used to move loads. within a considerable distance horizontally. Accordingly, lifting work was organized in the workplace in a different way than it is today. For example, in building construction it is assumed that the crane lifts the blocks from below directly into position, or from a place opposite the center of the wall from which it can transfer the blocks to two teams. work at each end of the wall. In addition, the crane operator, who normally commands the tire workers from outside the crane, can control the horizontal movement by means of a small rope attached to the load. Rotary cranes that allow rotating loads and are therefore particularly suitable for dockside work appeared as early as 1340. While ash blocks were lifted directly by slings, beams or clamps of demons (German Teufelskralle), other objects have been previously placed in containers such as pallets, baskets, wooden boxes or crates.

It is noteworthy that medieval cranes rarely had ratchets or brakes to prevent the load from running backwards. This curious absence is explained by the high frictional forces exerted by medieval wheels which normally prevent the wheels from accelerating out of control.

Using the harbor

According to the "current state of knowledge" unknown in ancient times, the stationary harbor crane was considered a new development of the Middle Ages. The typical harbor crane is a cylindrical structure equipped with double gears. These cranes are located in dry docks for cargo handling, where they replace or complement older methods of lifting such as saws, winches and yards.

Two different types of harbor cranes can be identified with different geographical distribution: While gantry cranes, which rotate on a central vertical axis, are commonly found in the Flemish and Dutch coasts, berths German inland and seaports often have tower cranes where the winch and wheels are housed in a solid tower with only the swingarm and rotating roof. Dockside cranes were not acceptable in the Mediterranean region and the highly developed Italian ports, where authorities continued to rely on the more labor-intensive ramp unloading method from the Middle Ages.

Unlike construction cranes where the working speed is determined by the relatively slow progress of the masons, harbor cranes often have dual wheels to increase loading speed. Two gears with an estimated diameter of 4 m or more are attached to each side of the shaft and rotate together. Their capacity is 2-3 tons, which seems to correspond to the usual size of sea cargo. Today, according to a survey, fifteen wheeled harbor cranes from pre-industrial times still exist across Europe. Some harbor cranes specialize in masts for newly built sailing ships, such as those in Gdańsk, Cologne and Bremen. Besides these fixed cranes, floating cranes, which can be flexibly deployed throughout the harbor basin, came into use in the 14th century.

Early modern period

A lifting tower similar to that of the ancient Romans was very effectively used by Renaissance architect Domenico Fontana in 1586 to relocate the 361-ton Vatican tower in Rome. From his report, it is clear that the coordination of lift between different drag teams requires considerable concentration and discipline, as if the force is not applied uniformly, excessive tension on the rope will cause they are broken.

Cranes were also used domestically during this period. The chimney or fireplace crane is used to rotate the pots and kettles over the flame and the height is adjusted with a trammel.

Industrial Revolution

Sir William Armstrong, inventor of the hydraulic crane.

With the onset of the Industrial Revolution, the first modern cranes were installed in harbors to load goods. In 1838, industrialist and businessman William Armstrong designed a hydraulic crane powered by water. His design used a ram in a sealed cylinder pressed down by pressurized fluid entering the cylinder and a valve that regulates the amount of liquid intake relative to the load on the crane. This mechanism, the hydraulic jig, then pulls the chain to lift the load.

In 1845, a plan was devised to provide tap water from distant reservoirs to households in Newcastle. Armstrong was involved in the scheme, and he suggested to the Newcastle Corporation that the excess water pressure in the lower part of town could be used to power one of its hydraulic cranes. he to load coal onto the barge in Quayside. He claimed that his invention would do the job faster and cheaper than conventional cranes. The company agreed to his proposal, and the test proved so successful that three more hydraulic cranes were installed on Quayside.

The success of hydraulic cranes led Armstrong to establish Elswick Works at Newcastle, to manufacture hydraulic machines for cranes and bridges in 1847. His company soon received orders for hydraulic cranes from Edinburgh and Northern Railways and from Liverpool Docks, as well as for hydraulic machines for the dock gates at Grimsby. The company had expanded from a workforce of 300 and annual production of 45 cranes in 1850, to nearly 4,000 workers producing more than 100 cranes a year by the early 1860s.

Armstrong spent the next few decades continuously improving the design of his crane; His most important innovation was the hydraulic accumulator. Where there was no on-site water pressure available for the use of hydraulic cranes, Armstrong often built tall water towers to provide pressurized water. However, when he supplied the crane for use at New Holland on the Humber Estuary, he was unable to do so, as the foundation was only sand. He eventually produced the hydraulic accumulator, a cast iron cylinder equipped with a piston that supported a very heavy weight. The plunger will slowly be raised, drawing in water, until the downward thrust of the ball is heavy enough to force the water beneath it into the pipes at high pressure. This invention allows to force a much larger volume of water through the pipes at a constant pressure, thereby greatly increasing the load capacity of the crane.

One of his cranes, commissioned by the Italian Navy in 1883 and in service until the mid-1950s, is still standing in Venice, where it is now in disrepair.